Some Known Incorrect Statements About Premier Aluminum Llc

Some Known Incorrect Statements About Premier Aluminum Llc

Blog Article

The Ultimate Guide To Premier Aluminum Llc

Table of ContentsWhat Does Premier Aluminum Llc Do?The Greatest Guide To Premier Aluminum LlcThe 2-Minute Rule for Premier Aluminum LlcThe 7-Minute Rule for Premier Aluminum Llc

(https://www.behance.net/garymartin24)Generally, a buyer's primary responsibility was to locate qualified and receptive suppliers. In some cases, buyers presumed that any supplier ready to contractually fulfill the purchase need was qualified. Nevertheless, utilizing inexpensive and unqualified suppliers can cause quality problems, and threw away time and cash in the long run. To aid you via the process, below are some things to take into consideration when picking the ideal metal casting vendor.

As an example, a firm that only utilizes the investment casting process will certainly attempt to market you on why that process is best for your application. However what happens if utilizing the sand spreading process is best for you and your demands? Rather, try to find a distributor that provides a series of casting processes so the ideal choice for YOU is chosen

If functioning with a solitary source for all of your casting requires is essential to you, the distributor needs to be varied in its capacities. When combined with other incorporated abilities, this can help simplify and compress the supply base. When choosing the right casting provider, mindful factor to consider needs to be offered to quality, solution, and cost.

All About Premier Aluminum Llc

Customers progressively pick casting providers who have machining abilities. This can stay clear of problem if flaws are discovered throughout machining. If a 3rd event is machining, it might result in "finger-pointing" concerning who is at mistake. Is it a casting concern or a machining issue? If the casting supplier discovers a problem throughout machining, the problem is fixed faster without conflict over whose mistake it is.

Issue or no, incorporated machining streamlines the supply chain and decreases dealing with time and shipping expense prior to the product makes it to the consumer. What do you need from your casting provider? Are you seeking somebody to simply deliver a steel element to your front door or do you need more? As an example, if you do not have in-house metallurgy know-how, validate that the vendor can provide advice in selecting the appropriate alloy based upon your specific application - Casting Foundry.

Some foundries are limited or specialized. Make sure the vendor can satisfy all your material or alloy demands to remove the requirement for numerous providers.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Research study the distributor's site. Talk to a sales representative or organization associate.

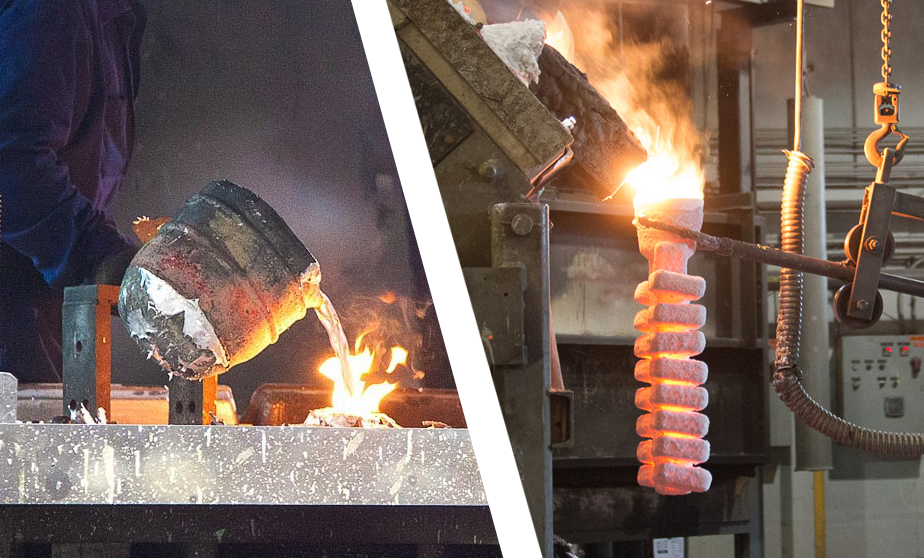

Aluminum is additionally lightweight and has navigate to this site good rust resistance, making it perfect for applications where weight and toughness are necessary elements. Furthermore, aluminum casting is an economical method of production, as it requires less energy and sources than other techniques. Iron spreading, on the other hand, includes pouring molten iron into a mold and mildew to produce a wanted shape.

The Best Guide To Premier Aluminum Llc

Iron spreading is also able to stand up to high temperature levels, making it ideal for use in applications such as engine parts and industrial machinery. Iron spreading can be much more pricey than aluminum casting due to the higher price of raw products and the power required to melt the iron. When making a decision in between light weight aluminum spreading and iron casting, it is essential to take into consideration the details needs of the application.

In conclusion, both light weight aluminum spreading and iron spreading have their own one-of-a-kind advantages and disadvantages. There are 3 sub-processes that fall under the classification of die spreading: gravity die spreading (or permanent mold casting), low-pressure die casting and high-pressure die casting. To get to the completed product, there are three primary alloys made use of as die spreading product to pick from: zinc, light weight aluminum and magnesium. Report this page